-

By h3si5

-

October 16, 2025

- 0 Comment

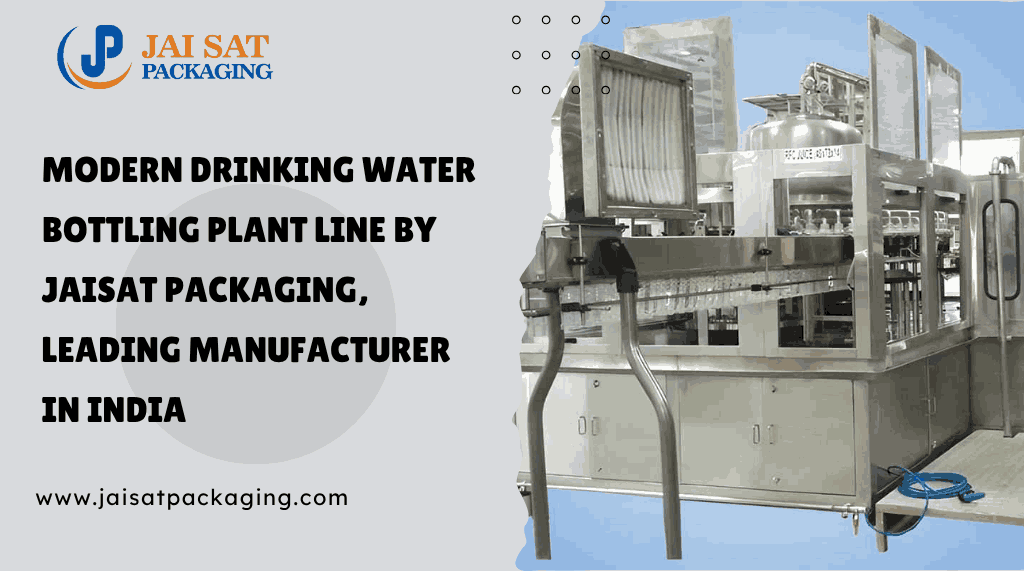

Modern drinking water bottling plant line by Jaisat Packaging, leading manufacturer in India

Jaisat Packaging — Top Drinking Water Bottling Plant Manufacturer in India

Introduction

Water is life — and packaging clean, safe drinking water at scale requires reliable machinery and expert support. Jaisat Packaging has built a reputation as a leading drinking water bottling plant manufacturer in India, delivering turnkey bottling solutions to entrepreneurs, large bottlers, and industrial clients across the country. In this post we’ll explore what makes Jaisat Packaging stand out, the types of bottling plants they provide, key technical features, benefits for businesses, and how to choose the right plant for your needs.

Why choose Jaisat Packaging?

When selecting a partner for a drinking water bottling plant, quality, compliance, and long-term support matter. Jaisat Packaging combines:

- Experience and expertise in designing bottling lines tailored to water — from mineral water to packaged drinking water.

- End-to-end solutions, including pre-installation consultation, equipment supply, installation, training and after-sales service.

- Compliance with standards for hygiene, food safety and electrical/mechanical reliability.

- Customisation: flexibility in production capacity, bottle types (PET, HDPE, glass), and automation level.

- Competitive pricing and reliable lead times, crucial for startups and scaling businesses.

These attributes have positioned Jaisat Packaging as a trusted drinking water bottling plant manufacturer in India.

Types of drinking water bottling plants offered

Jaisat Packaging supplies a range of bottling plants to fit different scales and budgets:

1. Small-scale / Semi-automatic plants

Ideal for startups and local brands, semi-automatic lines provide essential filling, capping and labelling functions with modest investment and easy maintenance.

2. Medium-capacity automated lines

Designed for growing businesses, these lines include automatic rinsers, fillers, cappers and labellers — boosting throughput while keeping operational costs under control.

3. High-capacity turnkey plants

For established brands and contract packers, Jaisat supplies fully automated turnkey plants with high-speed conveyors, multi-head fillers, integrated quality checks and SCADA-ready controls.

4. Specialized plants

Customized solutions for mineral water processing, purified water packaging, or lines with specific bottle formats and aseptic filling requirements.

Core components and technology

A professional drinking water bottling plant comprises multiple integrated systems. Jaisat Packaging ensures each component meets industry expectations:

- Bottle cleaning & rinsing units — ensuring hygiene before filling.

- Filling machines — volumetric, gravity or piston fillers depending on water type and flow.

- Capping machines — screw, snap or crown cappers with adjustable torque settings.

- Label applicators and shrink tunnels — for brand presentation and tamper-evident seals.

- Conveyors & accumulation systems — optimised for smooth flow and line balancing.

- Water treatment & RO systems (when supplied) — pre-treatment, reverse osmosis, UV sterilisation, and mineral dosing where required.

- Control panels & automation — PLC based controls, HMI interfaces and optional remote monitoring.

- Quality control stations — leak tests, weight checks and visual inspection systems.

These technologies work together to ensure consistent product quality and regulatory compliance.

Key benefits for bottlers

Investing in a Jaisat Packaging bottling plant brings tangible business advantages:

- Improved product safety and consistency — strict hygiene and precision filling reduce contamination and wastage.

- Cost efficiency — automation reduces labour costs, lowers per-bottle production cost and increases output.

- Scalability — modular designs let you expand capacity as demand grows.

- Faster time-to-market — experienced installation and training shorten commissioning time.

- After-sales support — spare parts, maintenance contracts and technical training ensure uptime.

These benefits explain why many firms prefer Jaisat Packaging as their drinking water bottling plant manufacturer in India.

Installation, training and after-sales service

A bottling plant purchase doesn’t end at delivery. Jaisat Packaging provides:

- Site survey and civil planning guidance to ensure correct layout and utility requirements.

- Professional installation and commissioning, performed by experienced technicians.

- Operator and maintenance training to local staff for smooth operation and rapid troubleshooting.

- Comprehensive after-sales support, including spare parts supply, preventive maintenance schedules and remote technical assistance where applicable.

This full-lifecycle support reduces downtime and protects your capital investment.

Sustainability and energy efficiency

Modern bottling operations must consider environmental impact. Jaisat Packaging helps clients adopt sustainable practices:

- Energy-efficient motors and drives to reduce electricity consumption.

- Water reclaim and zero-discharge options in treatment plants.

- Lightweight bottle handling and efficient layout design to minimise material usage.

- Support for recyclable packaging materials and guidance on responsible waste management.

These measures not only align with corporate responsibility goals but also reduce operating costs.

Cost considerations and financing options

Costs vary widely depending on automation, capacity and included systems (e.g., RO, labelling, palletising). Jaisat Packaging typically provides:

- Clear cost breakdowns (equipment, installation, training).

- Advice on total cost of ownership, including spare parts and labour.

- Guidance on financing options: vendor financing, bank loans or leasing arrangements to ease the upfront investment.

- A detailed proposal helps decision-makers forecast ROI and choose an affordable, scalable solution.

Conclusion

Choosing the right partner for your bottled water venture is a critical business decision. Jaisat Packaging, as a reputed drinking water bottling plant manufacturer in India, offers tailored machinery, expert installation, and dependable after-sales support — everything you need to launch or scale a successful bottling operation. Whether you’re a new brand entering the market or an established company expanding capacity, Jaisat’s turnkey approach reduces risk, ensures compliance, and helps you deliver clean, safe drinking water to your customers.

If you’re ready to explore options, request a consultation with Jaisat Packaging to receive a customised proposal and technical documentation suited to your requirements.