-

By h3si5

-

September 23, 2025

- 0 Comment

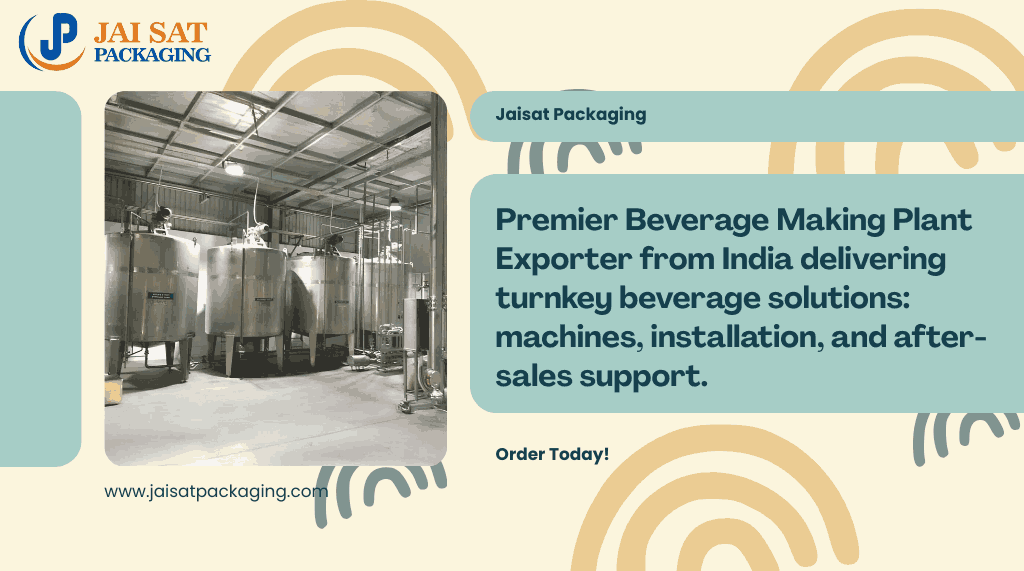

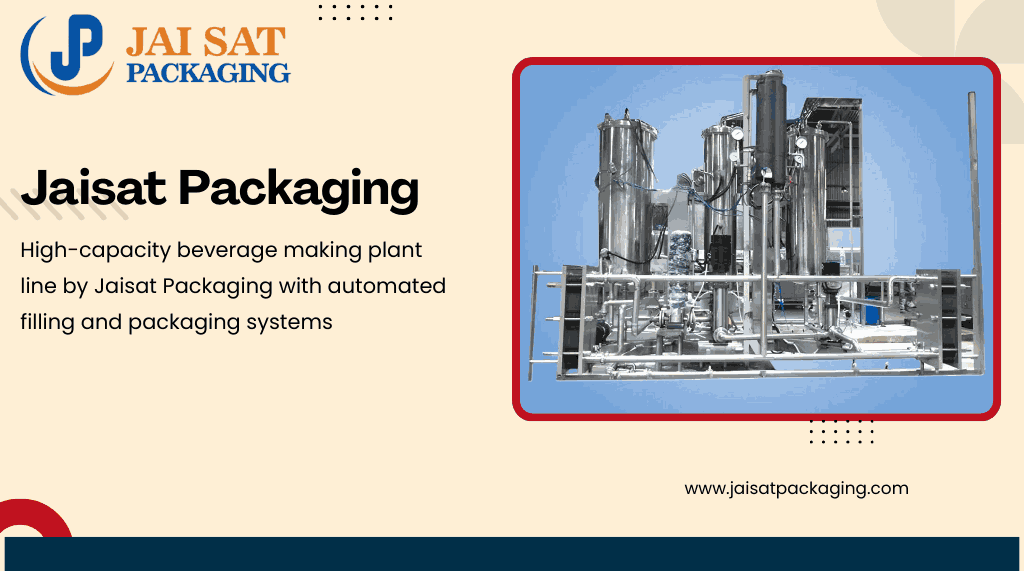

High-capacity beverage making plant line by Jaisat Packaging with automated filling and packaging systems

Jaisat Packaging — Trusted Beverage Making Plant Exporter from India

Introduction

India’s beverage industry is booming — from bottled water and juices to ready-to-drink teas and functional beverages. For entrepreneurs and established brands looking to scale production and enter export markets, a trusted partner for equipment and end-to-end plant solutions is essential. Jaisat Packaging has emerged as a dependable Beverage Making Plant Exporter from India, offering turnkey solutions that combine modern machinery, engineering expertise, and reliable after-sales service.

This post explains why Jaisat Packaging is a preferred choice for businesses seeking a complete beverage production setup, what services they offer, and how to choose the right beverage making plant for your needs.

Why choose a specialised beverage making plant exporter?

Setting up a beverage production facility involves many moving parts — formulation equipment, mixing tanks, filtration, pasteurization (if required), homogenization, filling lines, labeling, packaging, and quality-control systems. Working with a specialist Beverage Making Plant Exporter from India ensures you get an integrated solution tailored to your product, volume targets, and regulatory requirements. Export-capable vendors also understand international standards, customs, and export documentation — a major advantage if you plan to sell overseas.

About Jaisat Packaging

Jaisat Packaging is an experienced manufacturer and exporter of beverage processing and packaging solutions. With expertise spanning design engineering, machine manufacturing, plant installation, and commissioning, they serve startups, regional brands, and multinational clients. As a Beverage Making Plant Exporter from India, Jaisat Packaging focuses on reliability, energy-efficient designs, and compliance with food-safety standards.

Core product lines and capabilities

Jaisat Packaging offers a comprehensive range of machinery and systems for beverage production:

- Mixing and blending systems: Precisely engineered mixing tanks with agitators, dosing pumps, and automated recipe control for consistent beverage formulation.

- Filtration & water treatment: Reverse osmosis (RO), UV, and multimedia filtration tailored to beverage-grade water quality.

- Pasteurization and sterilization units: Thermal processing and aseptic options for shelf-stability and safety.

- Homogenizers: For emulsified beverages like milk-based drinks and some functional beverages.

- Filling machines: High-speed rotary and inline fillers for PET, glass, cans, and pouches with hot-fill and cold-fill options.

- Capping & sealing: Rotary cappers for screw caps, crown corks, and tamper-evident seals.

- Labeling & coding: Automatic labelers, sleeve applicators, and date/lot coding systems.

- Packaging lines: Shrink-wrap, tray-packing, and case-packing conveyors ready for palletizing.

- Automation & PLC control: Integrated PLC and HMI control for monitoring and recipe management.

- Spare parts & consumables: Filters, seals, gaskets and other parts for reliable plant uptime.

This wide product range allows Jaisat Packaging to assemble tailored production lines suited for water bottling, fruit juices, carbonated beverages, energy drinks, RTD tea/coffee, and dairy-based drinks.

Turnkey services — from planning to commissioning

What makes a good Beverage Making Plant Exporter from India stand out is the ability to deliver beyond standalone machines. Jaisat Packaging provides turnkey services:

- Site survey and layout planning — assessing space, utilities, and workflow to design efficient plant layouts.

- Engineering & civil coordination — integrating process piping, utilities (steam, chilled water, compressed air), and structural requirements.

- Factory acceptance testing (FAT) — pre-shipment performance checks to ensure machines meet specs.

- Installation & commissioning — on-site assembly, alignment, and performance validation.

- Training & SOPs — operator training and standard operating procedures for consistent product quality.

- After-sales support — remote assistance, spare parts supply, and periodic maintenance services.

These services reduce project risk and time-to-market, especially for exporters who must meet strict delivery timelines.

Quality, compliance and export readiness

When selecting a Beverage Making Plant Exporter from India, compliance with food safety and international certifications is crucial. Jaisat Packaging designs systems to meet:

- HACCP and GMP principles

- Food-grade material selection (SS304/316)

- Sanitary piping and CIP (Clean-in-Place) capability

- CE or other export-specific certifications on request

Their export documentation support, packaging for shipment, and logistics coordination help clients receive plant equipment safely and quickly.

Energy efficiency and cost optimisation

Modern beverage plants must be cost-effective. Jaisat Packaging incorporates energy-saving features such as frequency-driven motors, efficient heat-exchangers for pasteurization recoveries, and automated controls to reduce wastage. These measures lower operational costs and improve the sustainability profile of exported plants — an important consideration for international buyers.

Financing, modular solutions and scalability

Not every client needs a full-scale plant on day one. Jaisat Packaging offers modular, scalable solutions — small pilot lines that grow into full-capacity plants. They also assist clients with financing partners and phased deliveries, enabling brands to scale production aligned to market demand.

Who benefits from Jaisat Packaging’s solutions?

- Startups testing new beverage formulations with pilot or semi-automatic lines.

- Growing brands expanding capacity or entering new markets.

- Co-packers and contract manufacturers needing flexible lines for multiple products.

- Exporters and international buyers seeking turnkey plants compliant with foreign regulations.

How to choose the right beverage making plant

When evaluating a Beverage Making Plant Exporter from India, consider:

- Production capacity: Bottles per hour or liters per hour vs. target sales.

- Flexibility: Ability to handle different container types and product viscosities.

- Automation level: Manual, semi-automatic, or fully automated systems.

- Sanitation features: CIP, material finish, and hygiene design.

- After-sales service: Spare parts availability and technical support.

- Export expertise: Experience handling international shipments and certifications.

Request a detailed proposal and factory acceptance testing (FAT) documentation before purchase.

Conclusion

For brands and entrepreneurs looking to scale production or enter global markets, choosing the right equipment partner is vital. As an experienced Beverage Making Plant Exporter from India, Jaisat Packaging delivers not just machines, but complete plant solutions — from engineering and FAT to installation, training, and after-sales service. Their focus on quality, export readiness, energy efficiency, and modular scalability makes them a reliable partner for beverage projects of all sizes.

If you’re planning a new beverage facility or upgrading an existing line, contact Jaisat Packaging for a tailored proposal and technical consultation — and take the first step towards building a production line that meets international standards.