-

By h3si5

-

October 6, 2025

- 0 Comment

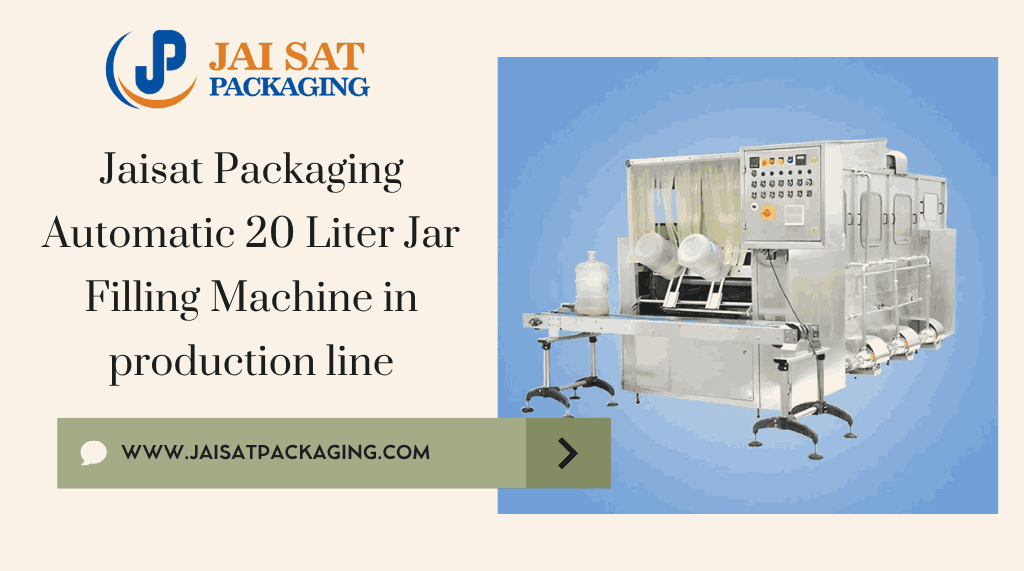

Jaisat Packaging Automatic 20 Liter Jar Filling Machine in Production Line

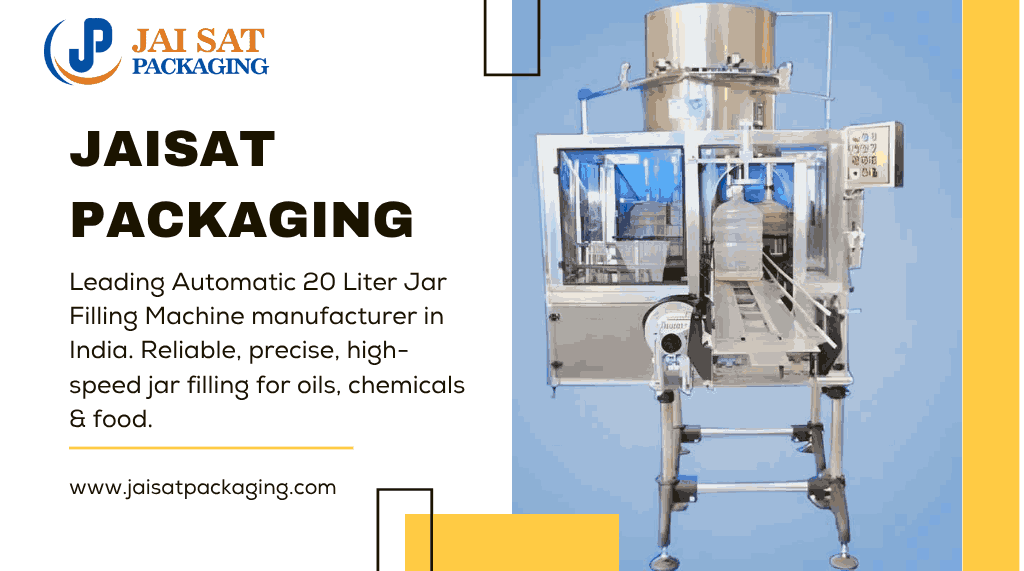

Automatic 20 Liter Jar Filling Machine manufacturer in India — Jaisat Packaging

Introduction

The industrial packaging sector demands speed, accuracy and reliability — especially when handling large-capacity containers like 20-litre jars. Jaisat Packaging, a trusted Automatic 20 Liter Jar Filling Machine manufacturer in India, delivers engineered filling solutions that help processors, packers and OEMs scale production while ensuring consistent fill accuracy, low downtime and regulatory compliance. In this comprehensive guide we explain product features, benefits, applications, ROI considerations and FAQs to help you choose the right automatic 20-litre jar filling system for your factory.

Why choose an automatic 20-litre jar filling machine?

Large-volume jars (20 L) are commonly used across edible oils, lubricants, chemicals, detergents and certain food pastes. Manual or semi-automatic fills are slow, error-prone and costly at scale. An automatic 20 Liter Jar Filling Machine from a reputable manufacturer in India solves these issues by delivering:

- High throughput — multiple jars per minute depending on product viscosity and machine configuration.

- Accurate fill control — electronic dosing systems reduce giveaway and overfilling.

- Cleaner operation — splash-free valves, drip guards and nozzles reduce waste and contamination.

- Reduced labor costs — automation frees staff for higher-value tasks.

- Better traceability & compliance — integrated PLC and HMI allow recipe storage, timestamps and batch records.

Core features of Jaisat Packaging machines

As a leading Automatic 20 Liter Jar Filling Machine manufacturer in India, Jaisat Packaging engineers each unit with features tuned to heavy-duty production:

- PLC control and HMI interface for recipe management, speed control and diagnostics.

- Servo or volumetric pump dosing options for precise, repeatable fills across viscosities.

- Adjustable filling heads to accommodate different jar geometries and closures.

- Stainless steel wet parts (SS304/SS316) for hygiene and corrosion resistance.

- Modular conveyor integration for in-line capping, labeling and sealing.

- Automatic jar detection & orientation to prevent misfills.

- Anti-drip nozzles & vacuum break systems for clean changeovers.

- Safety guards and E-stop for operator protection.

- Optional CIP (Clean-in-Place) and washdown capable designs for food and edible oil lines.

Typical configurations & technical options

Jaisat offers flexible configurations depending on product and plant needs:

- Filling principle: Gravity (for low viscosity), piston/servo pumps (medium to high viscosity), gear pumps (oils), peristaltic (abrasive or shear-sensitive fluids).

- Filling heads: Single head for low throughput, 2–6 heads for higher speeds.

- Conveyor options: Modular chain or flat belt conveyors sized for 20 L jar pitch.

- Control: Standalone PLC/HMI or shop-floor network integration (Modbus/Profinet).

- Power & utilities: Low power consumption designs; pneumatic options where compressed air is available.

- Material contact: Food-grade stainless steel; special linings for aggressive chemicals.

Industries and applications

An Automatic 20 Liter Jar Filling Machine manufacturer in India must serve diverse verticals. Jaisat’s machines are widely used for:

- Edible oils (mustard, sunflower, palm, blended oils) — precise volumetric dosing, hygiene focus.

- Lubricants & automotive fluids — oil-grade pumps, anti-foam handling.

- Chemicals & detergents — corrosion resistant parts and accurate dosing for concentrated formulas.

- Food pastes & sauces — piston or positive-displacement pumps to handle thickness without shear.

- Agro-inputs — pesticides and fertilizers in large jars requiring robust sealing.

Benefits and return on investment (ROI)

Investing in an automatic 20 L jar filling line from Jaisat Packaging results in measurable business gains:

- Lower cost per filled jar: reduced giveaway and higher throughput.

- Faster payback: typical ROI often achieved within 12–24 months depending on volume and labor costs.

- Consistent product quality: fewer customer complaints and returns due to accurate fills and secure closures.

- Scalability: ability to add capping, labeling and palletizing modules as demand grows.

- Compliance & reduced risk: hygienic design and traceability features help meet food safety or chemical regulations.

Installation, commissioning & training

Jaisat Packaging provides end-to-end support:

- Site assessment to confirm utilities, floor layout and material flow.

- Custom configuration recommendations based on product viscosity and jar design.

- On-site installation & commissioning — mechanical alignment, electrical hookup, PLC programming and process validation.

- Operator & maintenance training for safe, efficient operation and first-line troubleshooting.

- Spare parts kits & service contracts to minimise downtime.

Maintenance and uptime best practices

Maximising uptime requires predictable maintenance:

- Daily checks: nozzle cleanliness, conveyor alignment, sensor function.

- Weekly inspection: pump seals, belts and pneumatic connections.

- Planned downtime: schedule lubrication, filter changes and software backups.

- Stock critical spares: wear parts like seals, nozzles, and belts to avoid long OEE losses.

- Remote diagnostics: optional connectivity allows Jaisat’s service team to triage issues quickly.

How to choose the right supplier

Selecting an Automatic 20 Liter Jar Filling Machine manufacturer in India involves more than the machine price. Evaluate:

- Product experience: Does the supplier have domain knowledge for your product category?

- Customization capability: Can they adapt filling heads, pumps and controls to your jars?

- After-sales service: Local support, spare part availability and training.

- Compliance & safety credentials: Food-grade materials, CE/IS/other certifications as applicable.

- References & demos: Factory acceptance tests (FAT), customer references and on-site demos are invaluable.

Jaisat Packaging ticks these boxes — long experience across edible oil, lubricant and chemical sectors, local spares and commissioning teams, and strong aftermarket support.

Conclusion & call to action

When you need a reliable, high-performance solution for bulk jar packing, choose a proven Automatic 20 Liter Jar Filling Machine manufacturer in India. Jaisat Packaging combines robust engineering, project support and service to help you increase throughput, improve accuracy and lower operating costs. Whether you’re packing edible oils, lubricants, chemicals or food pastes, our modular machines are built to your product, your jar and your production goals.

Ready to upgrade your line? Contact Jaisat Packaging for a complimentary site evaluation, tailored quote and live demonstration of our Automatic 20 Liter Jar Filling Machine.