-

By h3si5

-

September 9, 2025

- 0 Comment

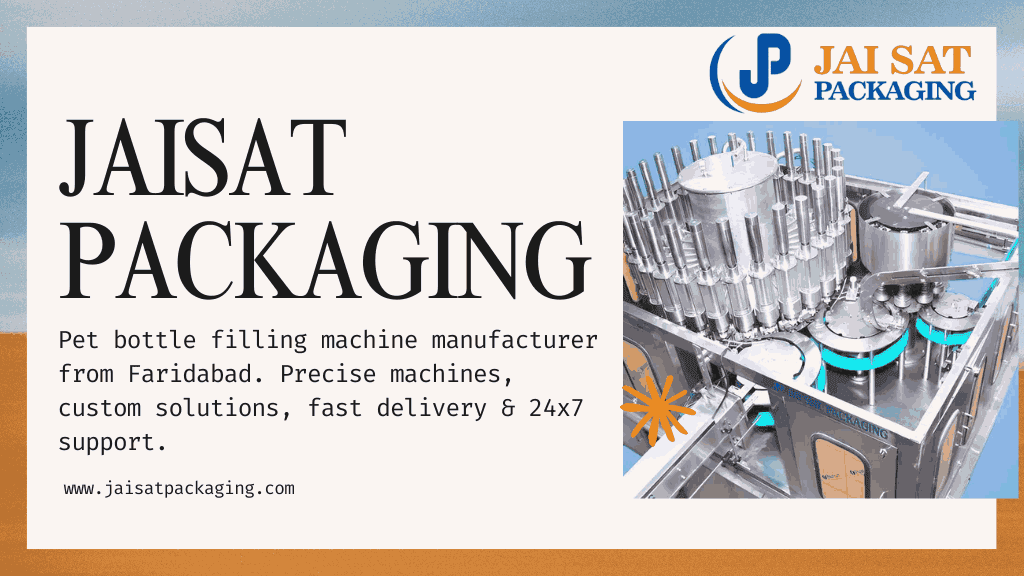

JAISAT PACKAGING PET bottle filling machine installed in a production line in Faridabad

JAISAT PACKAGING — Best Pet Bottle Filling Machines Manufacturer from Faridabad

Introduction

The packaging and beverage industries demand machines that are accurate, durable and easy to integrate into existing production lines. JAISAT PACKAGING, headquartered in Faridabad, is recognised for manufacturing robust PET bottle filling machines that meet these demands. From start-ups launching their first bottled product to established beverage houses expanding capacity, JAISAT’s machines combine practical engineering with a service-first approach.

About JAISAT PACKAGING

JAISAT PACKAGING specialises in PET bottle filling machinery and allied packaging equipment. With a focus on practicality and uptime, they design and fabricate machines with hygienic layouts, stainless-steel contact surfaces, and PLC-based controls for repeatable performance. Their product catalogue ranges from compact linear fillers to high-speed rotary monoblocs that integrate rinsing, filling and capping.

Key Advantages of JAISAT Machines

- Precision filling: Accurate volumetric and piston filling options reduce product giveaway and maintain consistent fill levels.

- Durable construction: Food-grade stainless-steel, sturdy frames and hygienic design reduce downtime and corrosion risk.

- Scalable solutions: Options suitable for small pilot lines up to large rotary machines for thousands of bottles per hour.

- User-friendly controls: PLC with HMI recipe management for quick product changeovers.

- Rapid local support: Manufacturing in Faridabad shortens lead times for spare parts and technical service.

- Energy efficiency: Modern drives and optimised pumps lower power consumption and operating costs.

Types of PET Bottle Filling Machines

- Monobloc Fillers: Compact lines that integrate rinsing, filling and capping — effective space savers for medium-speed operations.

- Rotary High-Speed Fillers: Ideal for large beverage plants and carbonated drinks where throughput is paramount.

- Linear Filling Systems: Cost-effective and flexible for lower-volume production or multiple SKUs.

- Specialist Fillers: Designed for viscous liquids, edible oils, syrups, and aseptic applications with appropriate pumps and sealing systems.

Technical Highlights

JAISAT emphasises technical features that matter on the shop floor:

- Modular construction: Simplifies maintenance and enables phased upgrades.

- Advanced pumping options: Piston, peristaltic or positive-displacement pumps to suit liquid properties.

- CIP compatibility: Clean-in-place features and easy-access panels to streamline sanitation.

- Low product giveaway: Precise nozzle design and fill algorithms reduce waste.

- Connectivity: Options for PLC/SCADA integration and remote diagnostics for predictive maintenance.

Customisation & Integration

A major strength of JAISAT PACKAGING is tailored engineering. Engineers work with clients from the design review and bottle-sample stage through to Factory Acceptance Testing (FAT). Common customisations include star-wheel pitch changes, bespoke conveyor constructions, quick-change nozzle assemblies, and communication protocols to integrate with existing ERP or SCADA systems.

Installation, Commissioning & Training

JAISAT offers end-to-end implementation: site survey, pre-installation checks, full commissioning and operator training. Commissioning ensures the line runs at target speeds, filling accuracy is verified, and safety interlocks are tested. Training covers routine maintenance, trouble-shooting and basic PLC operations to keep the line productive.

Industries & Typical Applications

- Beverages: Mineral water, juices, flavoured waters, and carbonated soft drinks.

- Food & Dairy: Edible oils, syrups and sauces.

- Pharmaceutical & Chemicals: Non-hazardous reagent and dosing applications.

- Cosmetics & Personal Care: Lotions, shampoos and liquid cosmetics requiring careful handling.

Quality Assurance & Spare Parts

Every machine undergoes material checks and performance verification prior to dispatch. JAISAT stocks commonly required spare parts and wear items to minimise downtime. Clients can purchase spare kits and recommended consumables to support long production runs.

Energy Efficiency & Return on Investment

JAISAT’s focus on efficient mechanical design and modern drive systems helps lower energy consumption and reduces operating costs. Typical ROI derives from reduced product giveaway, improved line uptime and lower labour requirements due to automation.

Safety & Compliance

Machines are built with operator safety in mind — guards, interlocks, emergency stops and adherence to statutory electrical safety norms. Contact parts use food-grade materials for hygiene-critical applications.

Maintenance & Service Contracts

Preventive maintenance packages are available to suit production cadence — from periodic inspections to full annual overhauls. Long-term service contracts can include priority spares, scheduled visits and remote diagnostics.

Choosing the Right Machine

- Assess throughput: Rotary machines for very high speeds; monoblocs for medium-line integration; linear systems for lower volumes.

- Understand liquid properties: Viscosity, foaming and particulate content guide pump and nozzle choices.

- Define bottle specifications: Accurate neck and body dimensions ensure correct handling and sealing.

- Plan line integration: Consider upstream rinsing and downstream capping, labelling and packing to enable smooth handoffs.

Conclusion

JAISAT PACKAGING from Faridabad stands out as a practical, service-oriented manufacturer of PET bottle filling machines. With an emphasis on robust design, precision filling and local support, JAISAT is well placed to help manufacturers increase throughput, reduce operational costs and maintain product quality. Whether launching a single SKU or upgrading a multi-line plant, JAISAT offers machines and services tailored to modern production needs.

Call to Action

For quotations, FAT scheduling or a site visit, contact JAISAT PACKAGING with details of your liquid, bottle dimensions and required throughput. Their engineering team will propose a tailored solution, prepare a detailed quote and assist through installation and commissioning.